Today our partner, Anton Julin, heading “Albus Pro” installation company, speaks about his experience of using iRidium in his work and highlights the most interesting moments of integrating Crestron and AV equipment.

Anton, how long have you been in the automation sphere and why you chose it?

I began to use automation in the times I worked in the cinema industry, and I guess even earlier in the 1990’s. With time automation began to dominate in the services my company provided.

How and when did you get acquainted with iRidium?

Initially, it was not me, but my colleague, Alexey Fabrikov, who driven by mere curiosity took a training course and used your product at a minor object. If I am not mistaken it was 1.5 version. Later on there was another project, a 150-200-square-meter apartment, where we decided to use your Product as a simple and inexpensive visualization solution, as the project did not feature Crestron equipment, that I usually worked with. The first thing that I liked was the capability to make an interface for Retina resolution. But there were a number of sad moments (at a certain time there were so many of them that I was about to give up this idea), but iRidium capability to use good graphics overweighed. And in the long run the project had to be finished. To tell the truth, it took a long time. My colleagues and the customer got bored. And though I liked the result, nobody else was excited, as they were bored with waiting. Thus, the evident conclusion was “The crucial factor in integrator work is speed! Now I use your product almost in all projects I make..

What tasks of your customers do you solve with «iRidium»? Has use of iRidium had any effect on your professional growth and business?

What tasks of your customers do you solve with «iRidium»? Has use of iRidium had any effect on your professional growth and business?

«When face to face we cannot see the face. We should step back for better observation». In short, it’s too early to speak about serious success. Rather yes, than no. The tasks are in fact rather numerous, as iRidium works directly with drivers. There is nothing else to say.

It is noticeable that in almost every installation you use Crestron equipment. What is the reason for the choice? Your personal preferences or equipment features?

Firstly, it is connected with the reliability of Crestron equipment, secondly, convenience of work.

What do you use Creston equipment for?

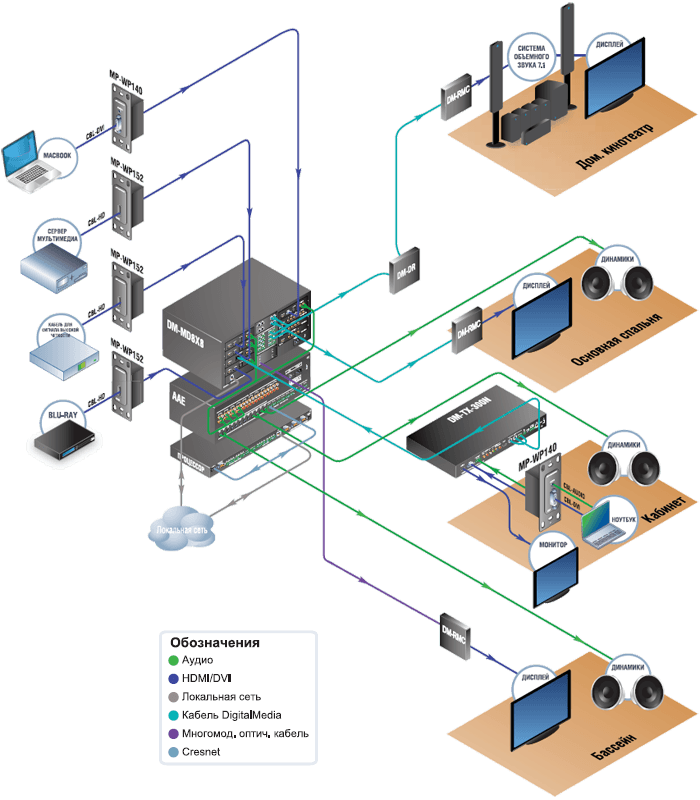

More often than not, Crestron equipment fulfils the function of the central controller – “the brain” of automation.

Do you usually create a centralized control system?

Not exactly … It’s a symbiosis of a centralized and a decentralized control systems. The decentralized system is the basis for controlling light, climate (heating) and part of passive security system. The centralized system allows to control more complicated climate systems (such as: ventilation and conditioning) as well as to control the work of the decentralized control system. Besides, the centralized control system is more suitable for controlling multimedia equipment.

What multimedia equipment do you prefer?

A lot depends her on the budget. If a customer can allow himself a level above average, I prefer to use «DigitalMedia» and «Sonnex» equipment by «Crestron».

Why do you like this equipment?

I think, because it’s easy to set and convenient to work with. It is reliable and allows to make up EDID-tables. And there are no problems with HDCP when connecting equipment.

Can you be more specific…

Can you be more specific…

EDID (Extended Display Identification Data) –«VESA» standard of data format, that contains basic information about the monitor and its features (including information about the manufacturer, maximum image size, color characteristics, manufacturer’s preset timing, frequency range).

HDCP (High-bandwidth Digital Content Protection) – technology to protect media contents, developed by «Intel», preventing illegal copying of high-quality signal.

Let’s imagine that there are 16 (!) different monitors (TV-sets) in your house. A smaller one in the kitchen, a bigger one in the guest room. When HDMI-splitter is connected, the source and the monitor exchange security protocols and supported tables. In case there are many monitors (TV-sets), this procedure takes a lot of time and it may annoy a user. And even after all turned-on monitors and the source have exchanged data, if one of the monitors is turned off (a wife turned off or on the TV in the kitchen), data exchange begins again. It means that the other monitors “freeze” again. And one more thing. If one of the monitors does not support a certain resolution at a certain frequency, a sort of collapse can happen.

Crestron equipment allows to avoid such nuances and its DM-switch sends data to a monitor, as if it were the only source and the monitor – the only monitor in the system. In other words, if there are 16 monitors in the house and they work with only one source, thanks to the correctly organized work of DM equipment by Crestron, each monitor thinks that it works with its own source. Besides, DM switch allows to set a table of supported resolutions (EDID) to avoid formats that are not supported by all monitors in the house.

Isn’t it easier to use identical monitors?

Yes, it is, but in real life it is practically impossible. If you want to have 60“or 80“ monitors in the sitting room, you may not want to have the same monitors in all other rooms (including kitchen and bathroom).

Sounds convincing. What do you use as the basis to control these systems?

I prefer to use PRO3, AV3, CP3 or AP3 processors, depending on the task, and build visualization on «iRidium».

What makes you choose iRidium, though the installation features Crestron equipment?

What makes you choose iRidium, though the installation features Crestron equipment?

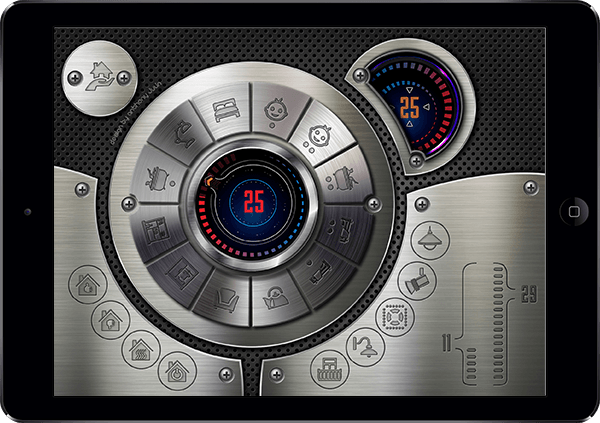

As I mentioned before, firstly, I like the capability to make beautiful visualization with animation. Secondly, I like that iRidium allows to talk to a definite equipment directly, without using the power of the central controller. Thus, I integrate different equipment, separately in the automation part and in the visualization part, without overloading the head equipment with extra calculations.

Do you make visualization on «Crestron»?

Yes. But mostly in those cases when I have to do something very reliable very fast. I prefer to make more serious visualization in the graphical part on the basis of iRidium. I’m looking forward to the release of the 64-bit version of iRidium Studio. It will give even more capabilities to create serious graphical projects.

How difficult is it in your opinion to make control projects in «iRidium»?

In my opinion at present it is the easiest and the most comprehensive visualization tool, though I’d like ot have certain moments improved.

What was the most difficult for you in mastering iRidium for Crestron?

Just some minor moments, connected with sending certain binary data, and some difficulties with sending floating point data.

What would you recommend to those who only start their work with iRidium? What to start with in interface design? What has to be taken into consideration?

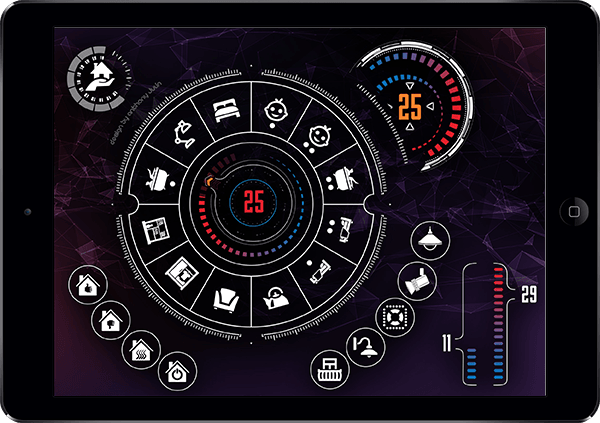

It’s difficult to say anything definite. I believe every integrator comes across certain difficulties. In my opinion the most difficult part is “Graphics”, as the control interface is, in fact, the only link that joins the complicated home automation equipment and a user. In general, the main difficulty is location of graphical items, controlling equipment.

Thus, from project to project an integrator struggles to find answers to the seemingly simple questions:

– how many graphical items to place on a definite page;

– what proportions to keep for the interface to look good and for the customer to easily touch the required buttons;

– symmetry or asymmetry? In both cases a unanimous numeric style of graphical items has to be kept. It means that no matter, how many graphical items there are in a definite zone, a certain number limit of them has to be kept in each zone, otherwise the interface tends to be chaotic. There must be a kind of order it helps a customer to handle the control interface easily. .

The following nuances have to be taken into consideration.

Comprehensive symbols. Let’s speak about lighting control as an example. A lot of integrators prefer to use a lamp image on a button that turns on a certain group of lighting, and this image looks dark when the light is turned off, and it looks lit when the light is tuned on. It’s one of the most wide-spread mistakes. If you speak to different users, you’ll easily learn that there are serious difficulties with using such an interface. In some cases it takes users years to remember which button is responsible for which lighting group, as all buttons look the same. To avoid it, each type of lights or a group of lights must have a different graphical image or a name, but names do not always look aesthetic. For this reason, it’s better to avoid button names. Though names seem to be the most comprehensive way to define a graphical item, they are not good enough, as, firstly, customers do not read button names, secondly, the right brain is not receptive to names but to graphical images. There is one more aspect – it’s difficult to place names in graphical items, as word length varies, and it’s a certain limitation.

Another thing is the interface concept. This term includes a lot. Initially simple things have to be thought about. How will a person understand where he is and what he can control? It’s very important to think how a user will “read” the interface. It’s evident that only a few users understand how to handle an interface themselves the first time they see it. But in general the integrator’s aim is an interface that users can easily understand on their own.

Navigation. What requires detailed thinking is how a user will move between interface pages and how easy it will be for him. This problem is not easy to solve, as an integrator’s engineer thinking is accompanied by the customer’s wishes, who, to tell the truth, may not understand what he really wants to see and what he will use or not use in the long run. We have to look into the future here.

Navigation. What requires detailed thinking is how a user will move between interface pages and how easy it will be for him. This problem is not easy to solve, as an integrator’s engineer thinking is accompanied by the customer’s wishes, who, to tell the truth, may not understand what he really wants to see and what he will use or not use in the long run. We have to look into the future here.

Graphics as an art. It’s not the same to be a good engineer, a good programmer and a good artist. What is required here is a sense of style and knowledge of programs that are not easy to master, as they have certain peculiarities. Even if you have mastered a tool, it does not mean that you will master the technique easily. Anybody can learn to put paint on the canvas, but only a few selected ones can paint anything worthwhile (and in our case a person must have a gift for technical design). It’s possible to ask a designer to make graphics, but many nuances appear here too. Firstly, you must write a very precise technical specification with regard to everything written above, secondly, you can’t be 100% sure that a hired designed can make right decisions on conceptual questions. Let’s imagine that as a result of your joint efforts you have a general concept, but this concept does not have such features as skeuomorphism or flat minimalism, color, texture, pattern. To put it shortly, the customer and his surroundings must like the interface. What if they do not like? Designer’s work has to be paid for. .

One more thing a beginning integrator may come across, is growing difficulty in the programming part in case complicated graphics is chosen (standard tools of iRidium Studio allow to make a lot, but they are not enough for serious projects). That’s why «JS» has to be used for more serious projects. I am only a beginner here and can’t give you serious advice. All I can share with you is that a trivial syntax mistake can easily make you work very difficult. So, I recommend using such apps as WebStorm», «Sublime» or «DreamWeaver». Pay more attention to syntax and general rules. In my time I made a lot of mistakes and could not understand why a script did not work. The reason was really simple – use of unallowed symbol in the function or variable name, for example. The apps I gave as an example drew my attention to these mistakes.

In conclusion, what has to be paid special attention to is mistakes made in the whole project. There can be a lot of them. The most popular of them are – a ”hiding” blank space, “C” symbol that looks identical in English and Russian, but if such mistakes are made somewhere in the script, it may take hours and even days to find them. It’s even difficult to imagine how many people suffered from such trivial mistakes. One has to be extremely attentive and check the work the work carefully and thoroughly. I prefer to do everything by small parts (projects) and then put them carefully together in a single project.

I’d like to draw attention to the importance of saving different project versions periodically. In case anything goes wrong, and the project file becomes impossible to use, it’ll be much easier to start with a previous version and not from the very beginning.

What would you like to improve/change in iRidium for easier and more convenient work?

What would you like to improve/change in iRidium for easier and more convenient work?

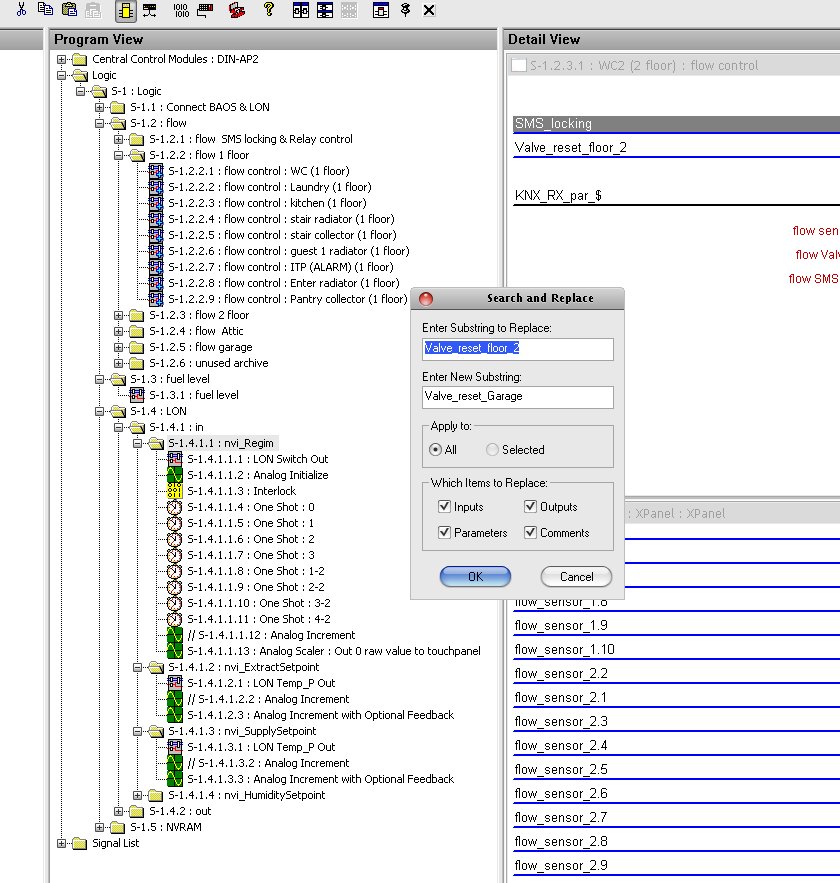

The most acute for me at the moment is a capability to copy a whole tree with folders and subfolders from one project to another, and a capability to rename a required part of item names, folders, etc., the way it is done in Crestron. In «Crestron» you can click with the right mouse button on the whole logics tree and change in the name of tree items the word “kitchen” for “Bedroom”, and after it the whole huge tree of folders, logical items, joins is renamed in a second. Besides, you can choose where exactly to rename, that is, in the names of joins, logical items, folders or everywhere. This function can save a lot of integrator’s time. And time is money. Personally I, being used to working with Crestron equipment always give very precise names to joins, logical items and folders. As a result at any time of day and night I can understand what this logics is responsible for by having one look at it. Of course it takes a lot of time to give correct names to all items, but having created a tree once, you can simply copy it and rename items in a bundle. In iRidium Studio it is done manually, it takes a lot of time and leads to mistakes. .

I’d also like a capability to used packed video with alfa-channel as an item. I’ve already spoken about it.

And one more important thing – release of 64-bit editor of iRidium Studio. Because problems with operation memory made me freeze some of my interesting projects. Here I’d also like to mentions a capability to chose whether to pack into zip or not, when saving an object, not to spend time of archiving hundreds of project versions, as, I repeat myself, time is the most valuable thing in integrator’s work.

And the painful “Slider” question, make them like in «Crestron».

Do you have any wishes to iRidium mobile team on further work?

First of all, I’d like to wish you success and prosperity. And, please, remember about your partners, their needs, requests and remarks. Let your fast reaction and good solutions be faithful friends of your success.